Rebonding

Rebonding machines

Our Rebonding Machine is a fully integrated and highly adaptable solution to repurpose waste materials such as plastic and other industrial residues.

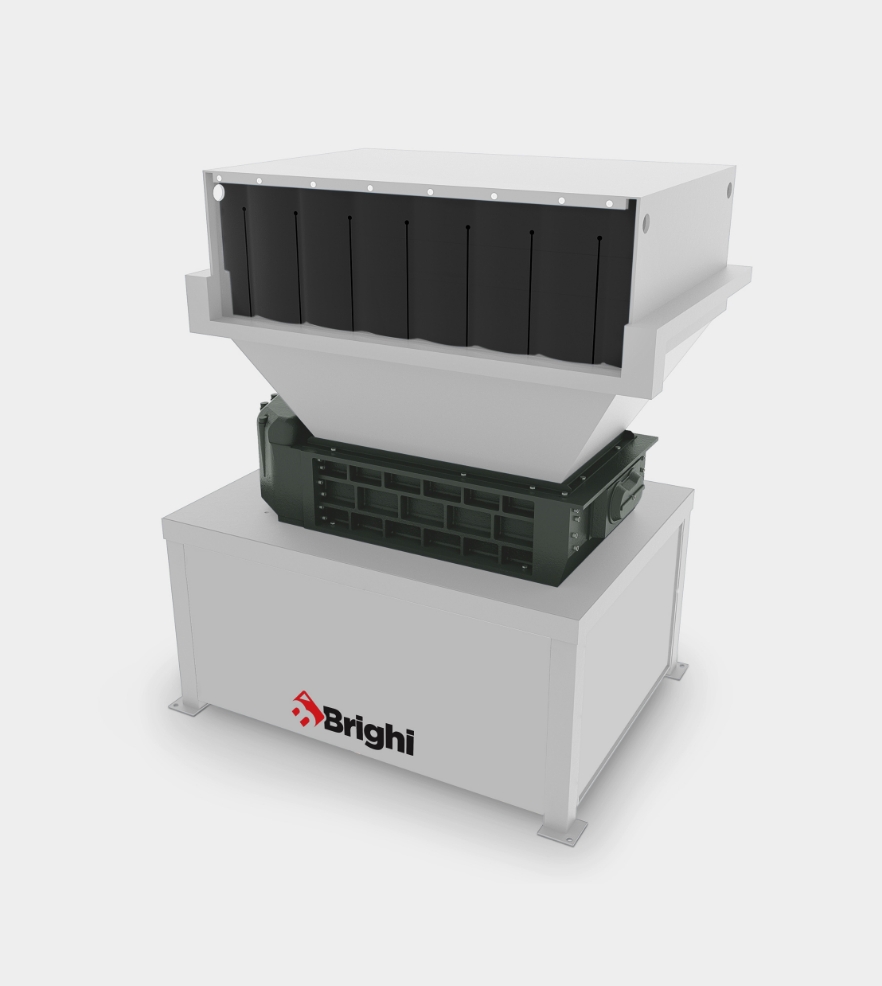

The system features a reinforced platform supporting a sealed reaction chamber, where the pre-treated material is combined with reactive components. Inside the chamber, an agitator mechanism continuously stirs the mixture to ensure uniformity and prevent premature solidification.

Once the blending process is complete, a controlled discharge system opens the chamber base, releasing the compound directly into a mould positioned below.

The filled mould is then manually or automatically positioned under the pressing unit, where it undergoes compression. The pressing duration can be adjusted depending on the desired final density and mechanical performance of the block.

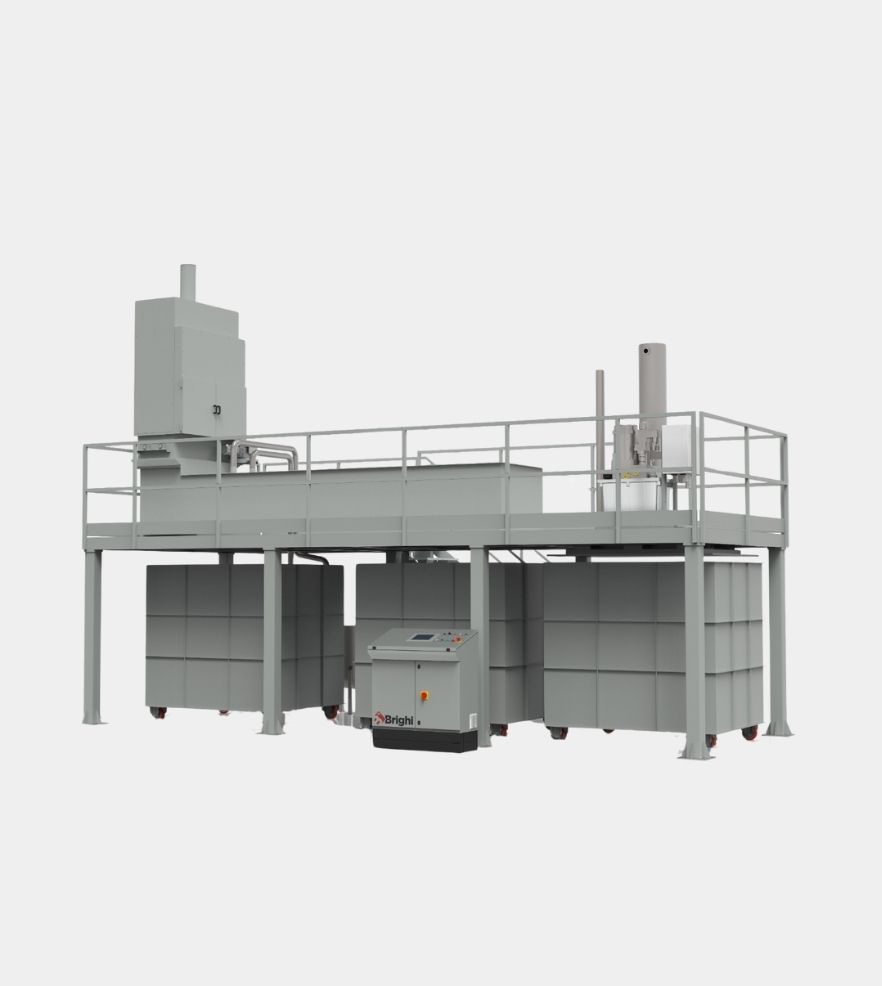

A typical production line includes:

- a shredding unit for initial material reduction,

- a mixing system for combining additives and binders,

- and the agglomerated block forming machine for final shaping and compaction.

This process results in durable recycled blocks with customizable density and structure — ideal for reuse in construction, insulation, or industrial applications.

Applications:

Wood

Tire

Plastic

Paper

Industrial

Power range: from 30 kW to 60 kW (40 HP to 80 HP)

Mold size: up to 2000 x 2500 mm (79” x 98”)

Available models: 3

Real life applications

Installation: Mexico

This rebonded block forming line is made of a shredder, a mixer and the rebonding machine. It uses polyethylene, polystyrene and polyurethane scraps of different types and densities to create homogeneous blocks of rebonded foam, a reusable material that can be used in several applications, among which bedding, insulation and automotive.

Contacts

Brighi USA Inc.

1800 West Loop South Suite 1600

HOUSTON, TX 77027

[email protected]

+1 706 986 0072