Compactors

Compactors

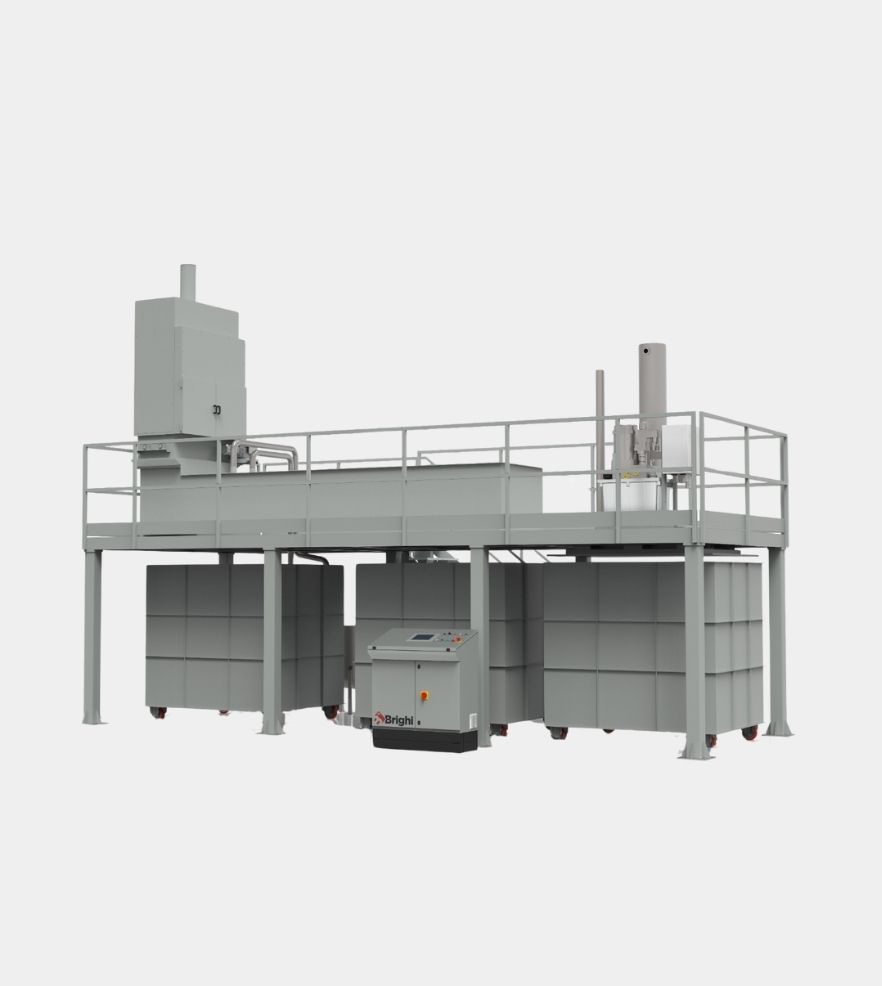

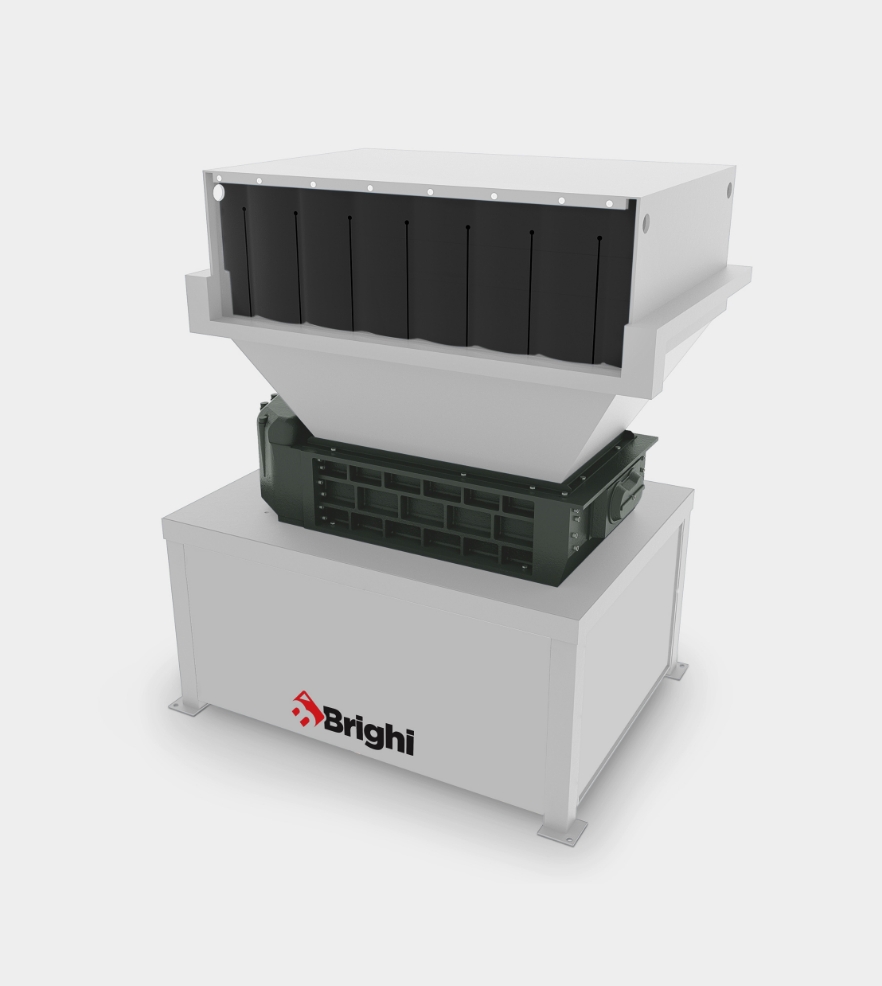

Our industrial compactors optimize waste management by significantly reducing the volume of recyclable and non-recyclable materials, integrating seamlessly into existing production lines. They deliver the pressing power required to transform bulky material – such as paper, plastics, PET bottles, wood chips, and metals- into compact, manageable bales. The blade-control cutting system keeps bale quality consistent, and a sophisticated side-mounted tying unit minimizes the machine’s footprint. Capable of handling continuous material flows, the machine is also engineered to optimize energy use, helping to curb acoustic emissions for a quieter workspace.

By minimizing the waste volume, compactors reduce storage space requirements, lower transportation costs, and contribute to smoother internal logistics. In this way the compaction process not only increases the economic value of recyclable waste throughout the supply chain but also plays a vital role in environmental impact reduction, generating a virtuous circle.

Applications:

Wood

Plastic

Paper

Organic

Metal

Industrial

Compactation force: from 2t to 60t (4000lb to 120000lb)

Compacting chamber size: from 600x450x900h mm (23.6" x 17.7" x 35.4") to 2300x1100x800h mm (90.5" x 43.3" x 31.5")

Available models: 16

Real life applications

Installation: Canada

A wood-processing site in Canada adopted our horizontal compactor to manage production offcuts and shavings. The machine’s consistent compression performance allowed for better internal logistics and fewer waste pickups, optimizing both costs and space usage.

Contacts

Brighi USA Inc.

1800 West Loop South Suite 1600

HOUSTON, TX 77027

[email protected]

+1 706 986 0072